Evaluating IT solutions for manufacturing

Discover how to evaluate IT solutions for manufacturing with a step-by-step guide.

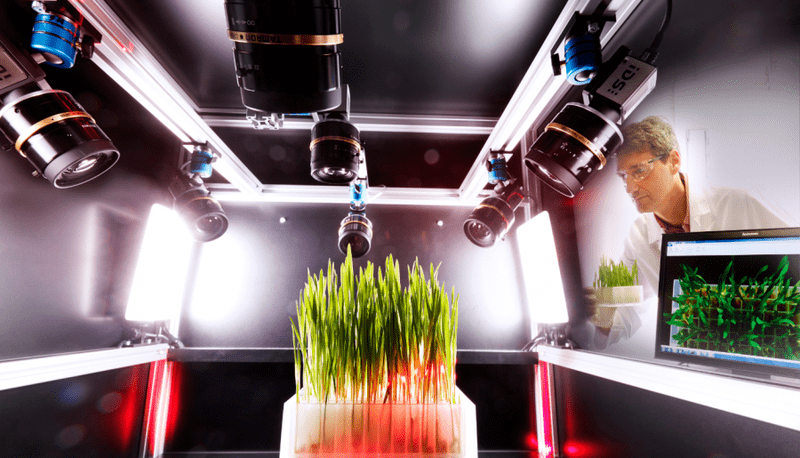

This (anonymous) bioscience multinational is leading the way thanks to automated phenotyping.

Phenotyping is one of the activities of this international group operating worldwide in pharma, health, and biotech. Together with lab technicians, USoft developed an automated phenotyping solution.

Lab technicians experiment with an almost infinite number of organic compounds. Each experiment contains photographs from multiple types of cameras. The lab technicians reported that they could no longer manage the huge volumes involved in high-speed phenotyping. Too much manual labor was involved in the process of experimentation, storage, and analysis, which caused them to fall behind. Moreover, organizing and searching through the data folders was problematic.

One of the major advantages of USoft low-code is its flexibility. Lab technicians prefer to implement optimizations in processes independently, which is now possible.

More on low-code application development

Testing high volumes of substances in a structured, consistent, and traceable manner. Laborators face limited laboratory capacity and limited resources. They wanted to do more experiments in the same time.

The business rules approach offered by the USoft platform is specifically suited for developing complex, data-intensive and rule-intensive applications. Because of using business rules, the main software solution is very agile, which makes future changes and additions easy to perform. If something changes, it is more transparent what is the effect on other pieces of the program.

USoft spoke extensively with the lab technicians responsible, and it quickly became apparent that this could be easily automated using USoft's low-code platform. The full project result is a state-of-the-art phenotyping system that will automatically organize- and analyze the correct images. This will enable researchers to perform analysis to determine the best strategy to reach their goals.

Analysis of +30.000 samples per day in a structured, consistent, and traceable manner. Decreased error margins by 80%.

Lab results are delivered 10x faster than before. That is why they are now a leader in product development.

Up to 95% repetitive operations and manual work have been removed from the process.

More control of production processes with ICT Group and USoft.

A comprehensive Pharmaceutical Rebate Information Management System (PRIMS) to manage the state based drug rebate program.

A comprehensive Pharmaceutical Rebate Information Management System (PRIMS) to manage the state based drug rebate program.

Discover how to evaluate IT solutions for manufacturing with a step-by-step guide.

Fortunately, this is not the case. This short article explains why not.

Common IT constraints in the manufacturing industry and actionable strategies to solve them.